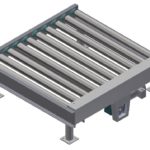

Chain Driven Live Roll Conveyors (CDLR) are used to handle large product, generally pallet loads. These can be had in light duty (LD), medium duty (MD), and heavy duty (HD) Series.

Overview

Chain Driven Live Roll Conveyors (CDLR) are used to handle large product, generally pallet loads. These can be had in light duty (LD), medium duty (MD), and heavy duty (HD) Series.

OPTIONAL EQUIPMENT:

- Built to Your Specifications:

Effective widths, lengths and roller spacing’s listed in this catalog are only general guidelines. And variation is easily accommodated. Notches, special drive bases, centering lanes, etc. can be provided. Conveyors can be built directly from your blueprints.

- Drive Under Slung or Top Mounted:

Reducer-motor unit mounted underneath conveyor(on top) and within the side frames

- Conveying Speed:

Several constant and variable speeds are available. Variable speed options include DC motor and controller, AC frequency controllers and variable pitch sheaves. Note: Capacity is affected by speed change.

- Other Rollers:

Other roller and bearing options are available

- Every Other Roller Powered:

This option allows rollers to be spaced closer together. Example for 2 1/2 in. diameter rollers with 60A15 sprockets: With EVERY roller powered, roller centers are limited to 4 1/2in. to allow for sprocket clearance. With EVERY OTHER roller powered, 3 in. roller centers are possible. Warning- Special safety consideration required.

- Powered Both Sides:

Allows rollers to be spaced closer together with every roller powered. Every other roller driven on one side and remainder of rollers driven on opposite side. Chain guards both sides. Specify effective width.

- Coated Rollers :

Rollers available zinc plated, chrome, urethane coated or teflon coated.

- Clutch:

Mounted between motor and reducer. Provides soft start and intermittent overload protection.

- Brake:

Mounted between motor and reducer. Provides fail-safe stopping of conveyor when motor is not running.

- Pop-Up Stops:

Manual or pneumatically operated roller, blade or pin stops mounted to underside of conveyor. Raises above conveyor surface to stop product.